The CUET PG Textile Engineering exam 2025 is scheduled for 29th March 2025 (Shift 3). After the examination, candidates will be able to download the CUETPGTextileEngineeringquestionpaper2025, answer key, and solution PDF. The exam evaluates knowledge in textile manufacturing, yarn and fabric technology, textile testing, fiber science, textile machinery, and quality control.

Candidates are required to answer 75 questions within 60 minutes, totaling 300 marks. Each correct answer earns 4 marks, and 1 mark is deducted for every incorrect answer.

CUET PG Textile Engineering 2025 Question Paper with Solutions PDF

| CUET PG Textile Engineering Question Paper with Solutions PDF | Download PDF | Check Solutions |

In ________, the package is driven in frictional contact with the drum.

In ________, the yarn passes through two plates in which one plate is the baseplate and the other is a weighing plate.

In case of plain weave fabric, the respective warp and weft counts are 30 tex and 20 tex, with 40 ends per cm and 30 picks per cm. The warp has 10% crimp and weft also 10% crimp. Calculate the weight of fabric in grams/square meter.

In ________ system, a warping beam with a complex pattern of colored stripes is obtained.

In the slasher sizing machine, the principle involved in drying the wet warp sheet by physical contact with a hot drum surface is ________.

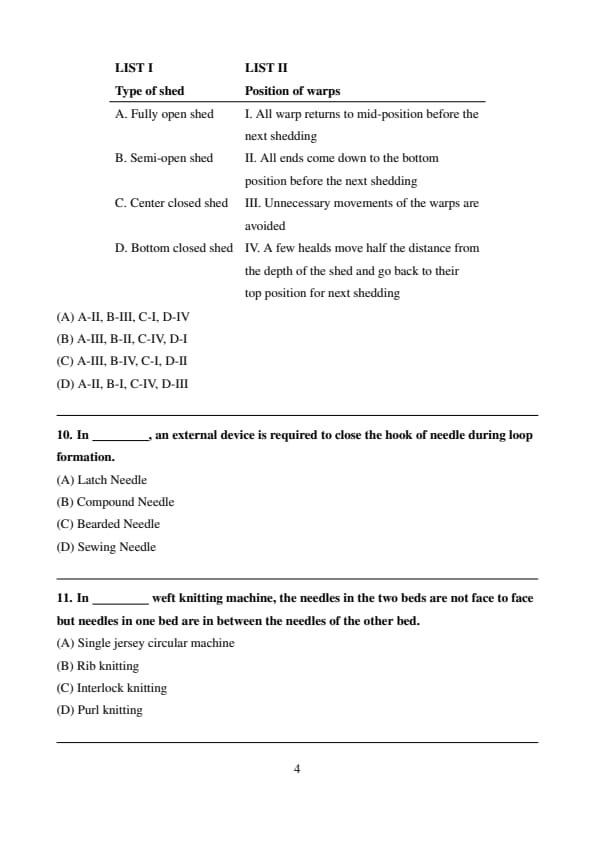

To prevent the growth of microorganisms, ________ is added to the size paste.

The material flow of the warp sheet through different zones in a sizing machine is ________.

A. Drying zone

B. Size box zone

C. Beaming zone

D. Creel zone

The ________ machine is used to produce a suitable package of weft yarn for a shuttle loom.

In ________, an external device is required to close the hook of needle during loop formation.

In ________ weft knitting machine, the needles in the two beds are not face to face but needles in one bed are in between the needles of the other bed.

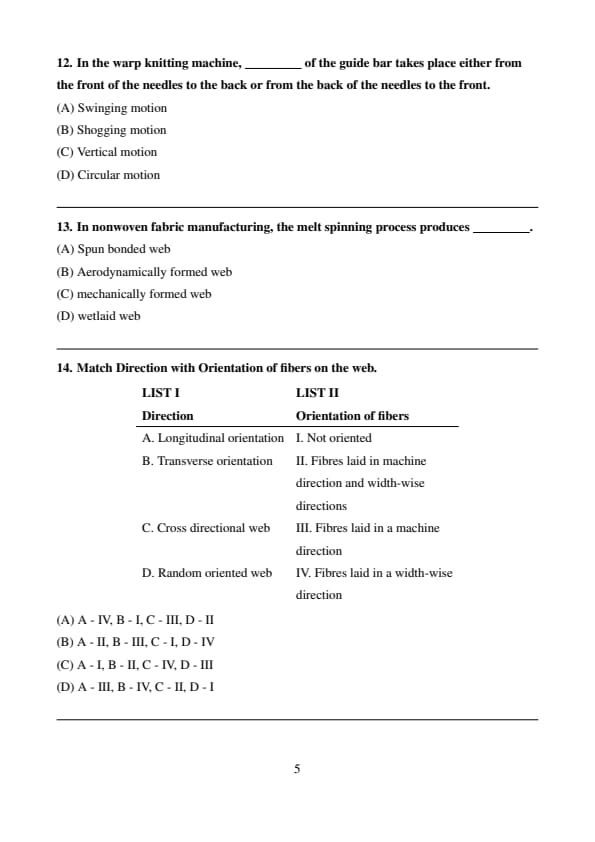

In the warp knitting machine, ________ of the guide bar takes place either from the front of the needles to the back or from the back of the needles to the front.

In nonwoven fabric manufacturing, the melt spinning process produces ________.

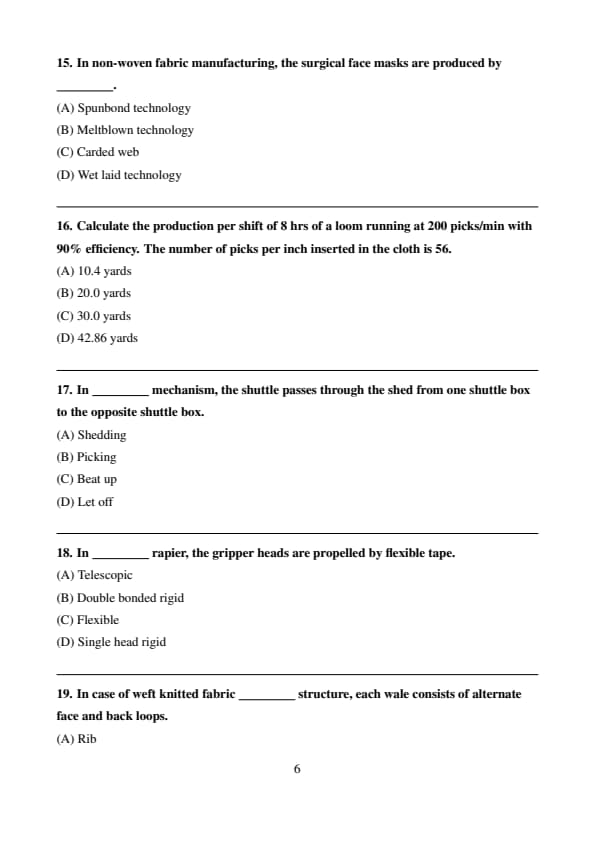

In non-woven fabric manufacturing, the surgical face masks are produced by ________.

Calculate the production per shift of 8 hrs of a loom running at 200 picks/min with 90% efficiency. The number of picks per inch inserted in the cloth is 56.

In ________ mechanism, the shuttle passes through the shed from one shuttle box to the opposite shuttle box.

In ________ rapier, the gripper heads are propelled by flexible tape.

In case of weft knitted fabric ________ structure, each wale consists of alternate face and back loops.

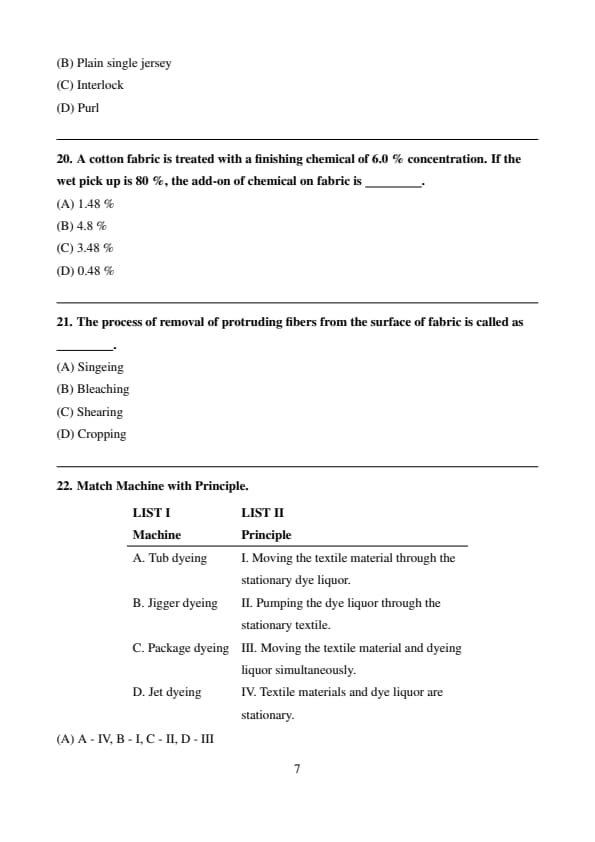

A cotton fabric is treated with a finishing chemical of 6.0 % concentration. If the wet pick up is 80 %, the add-on of chemical on fabric is ________.

The process of removal of protruding fibers from the surface of fabric is called as ________.

Objectives of scouring of cotton.

A. To remove natural fatty matter from textiles.

B. To remove added fatty matter from textiles.

C. To remove pectins from textiles.

D. To remove coloring matter from textiles.

Process sequence for polyester/wool blended knitted goods (Crisp handle).

A. Light brushing.

B. Open steam (allowing full relaxation).

C. Decatising.

D. Close cropping on face side of fabric.

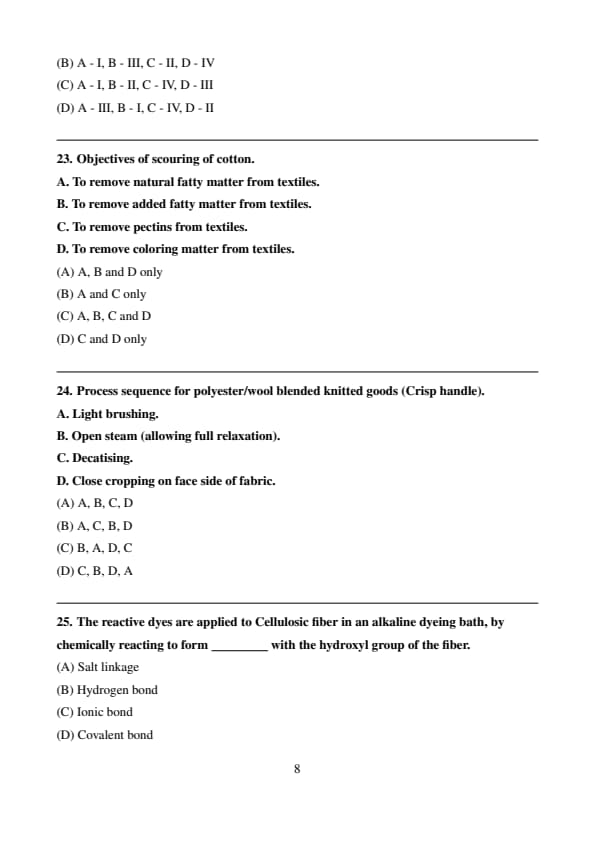

The reactive dyes are applied to Cellulosic fiber in an alkaline dyeing bath, by chemically reacting to form ________ with the hydroxyl group of the fiber.

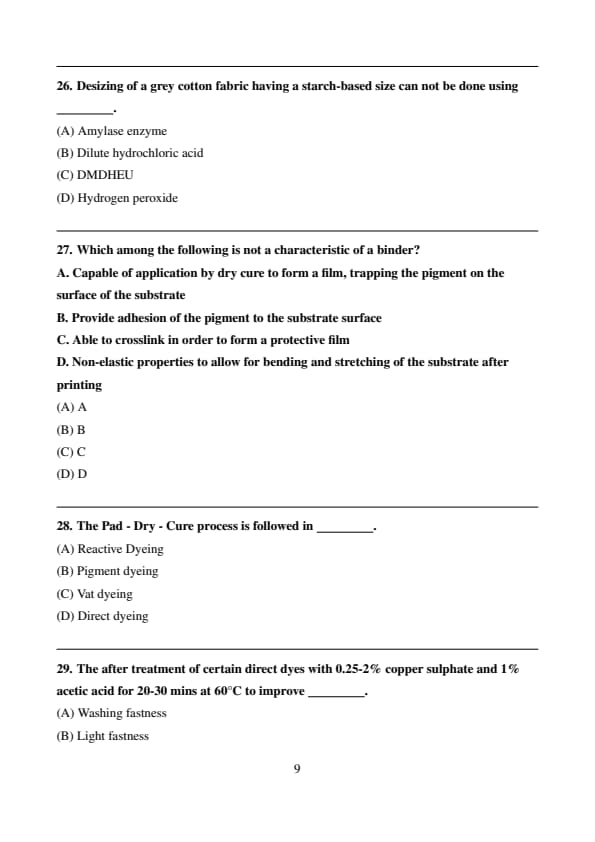

Desizing of a grey cotton fabric having a starch-based size can not be done using ________.

Which among the following is not a characteristic of a binder?

A. Capable of application by dry cure to form a film, trapping the pigment on the surface of the substrate

B. Provide adhesion of the pigment to the substrate surface

C. Able to crosslink in order to form a protective film

D. Non-elastic properties to allow for bending and stretching of the substrate after printing

The Pad - Dry - Cure process is followed in ________.

The after treatment of certain direct dyes with 0.25-2% copper sulphate and 1% acetic acid for 20-30 mins at 60°C to improve ________.

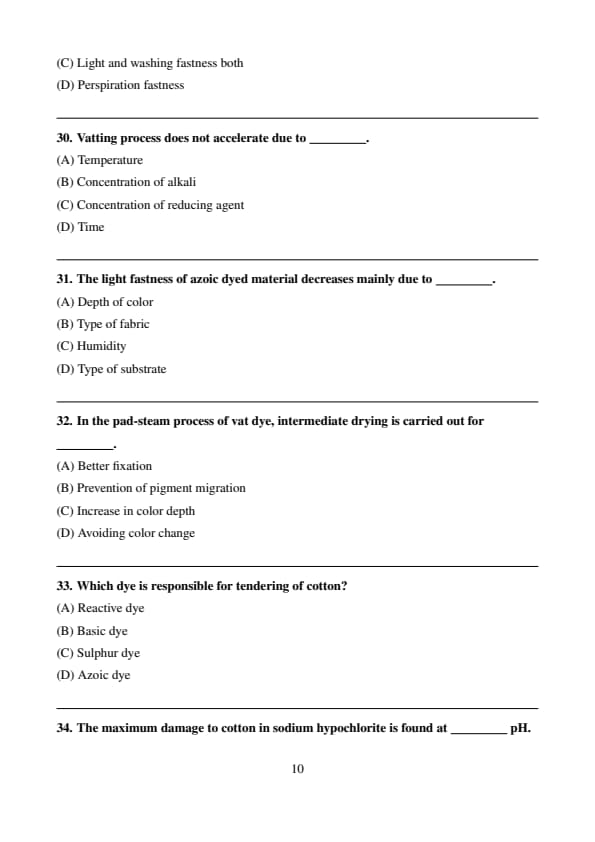

Vatting process does not accelerate due to ________.

The light fastness of azoic dyed material decreases mainly due to ________.

In the pad-steam process of vat dye, intermediate drying is carried out for ________.

Which dye is responsible for tendering of cotton?

The maximum damage to cotton in sodium hypochlorite is found at ________ pH.

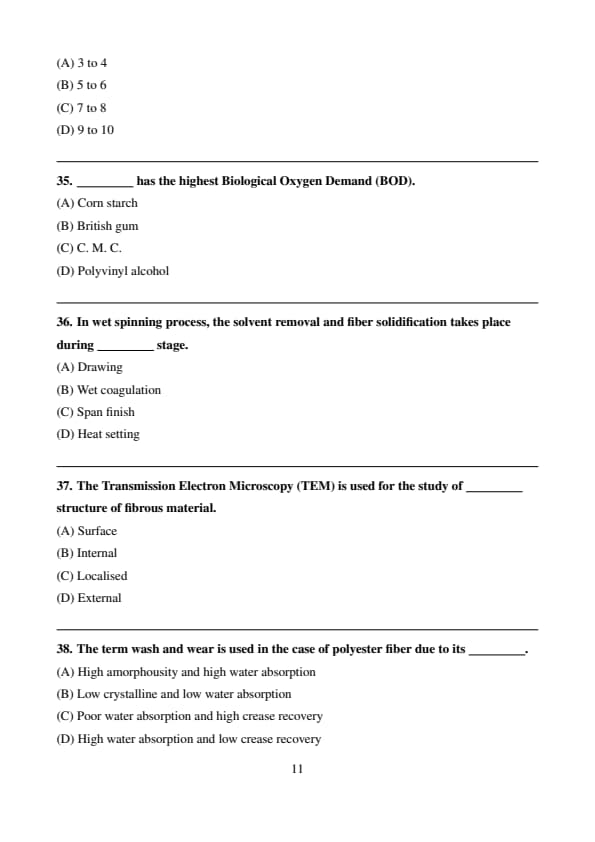

________ has the highest Biological Oxygen Demand (BOD).

In wet spinning process, the solvent removal and fiber solidification takes place during ________ stage.

The Transmission Electron Microscopy (TEM) is used for the study of ________ structure of fibrous material.

The term wash and wear is used in the case of polyester fiber due to its ________.

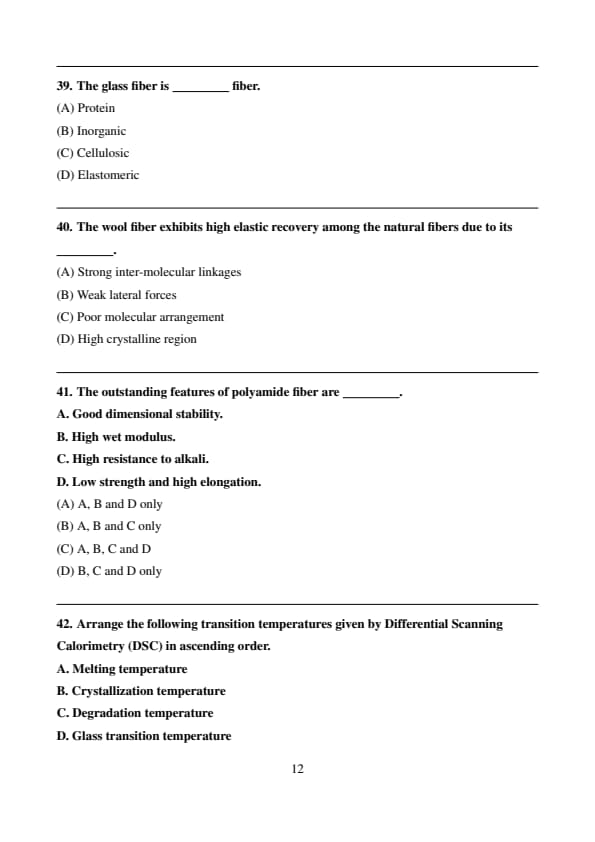

The glass fiber is ________ fiber.

The wool fiber exhibits high elastic recovery among the natural fibers due to its ________.

The outstanding features of polyamide fiber are ________.

A. Good dimensional stability.

B. High wet modulus.

C. High resistance to alkali.

D. Low strength and high elongation.

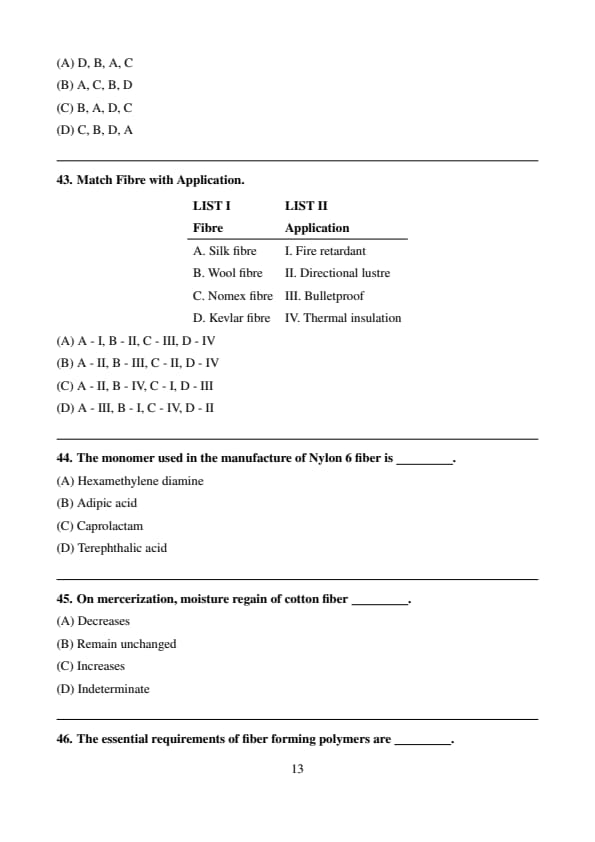

Arrange the following transition temperatures given by Differential Scanning Calorimetry (DSC) in ascending order.

A. Melting temperature

B. Crystallization temperature

C. Degradation temperature

D. Glass transition temperature

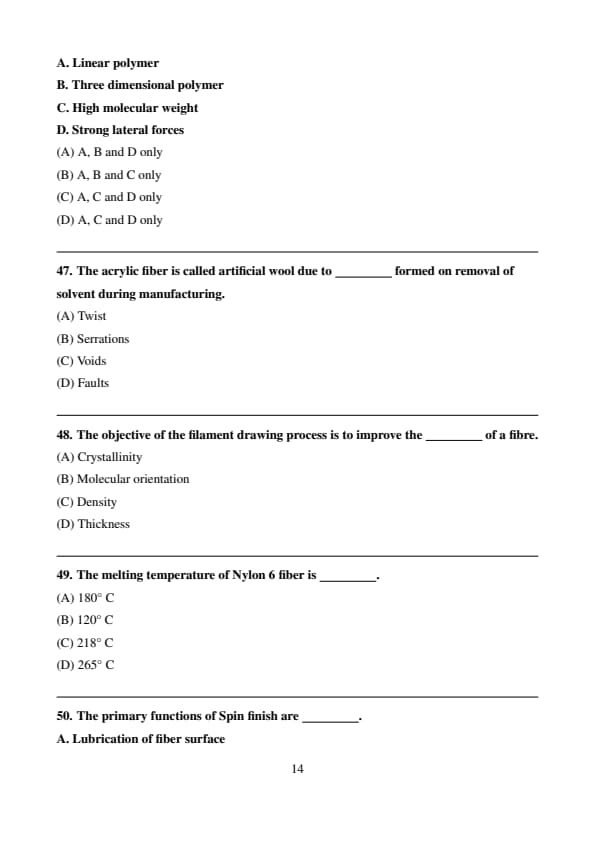

The monomer used in the manufacture of Nylon 6 fiber is ________.

On mercerization, moisture regain of cotton fiber ________.

The essential requirements of fiber forming polymers are ________.

A. Linear polymer

B. Three dimensional polymer

C. High molecular weight

D. Strong lateral forces

The acrylic fiber is called artificial wool due to ________ formed on removal of solvent during manufacturing.

The objective of the filament drawing process is to improve the ________ of a fibre.

The melting temperature of Nylon 6 fiber is ________.

The primary functions of Spin finish are ________.

A. Lubrication of fiber surface

B. Drawing of filaments

C. Antistatic action

D. Cohesion of filaments

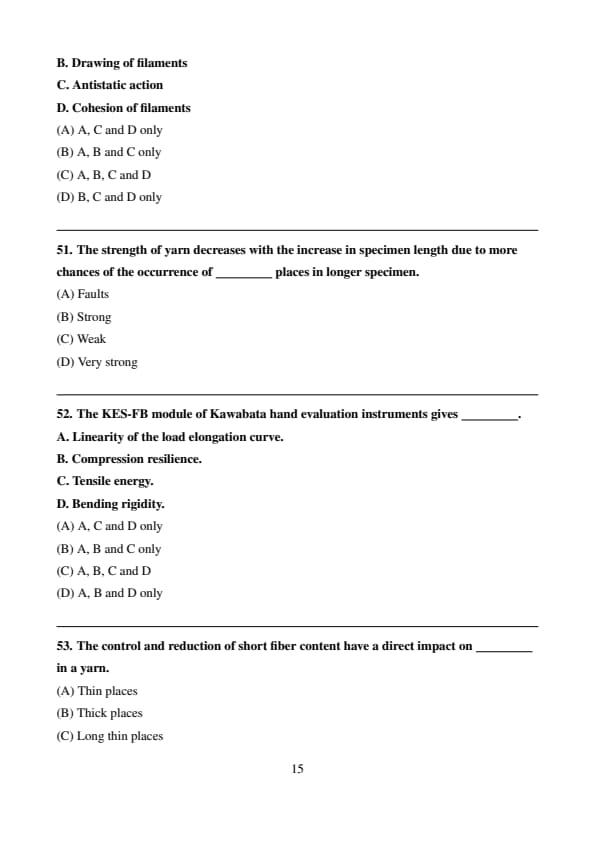

The strength of yarn decreases with the increase in specimen length due to more chances of the occurrence of ________ places in longer specimen.

The KES-FB module of Kawabata hand evaluation instruments gives ________.

A. Linearity of the load elongation curve.

B. Compression resilience.

C. Tensile energy.

D. Bending rigidity.

The control and reduction of short fiber content have a direct impact on ________ in a yarn.

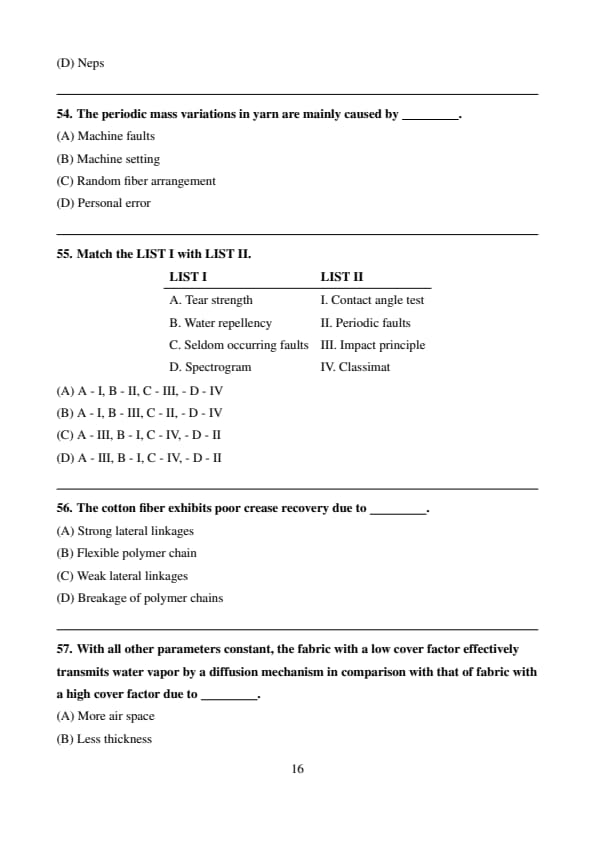

The periodic mass variations in yarn are mainly caused by ________.

The cotton fiber exhibits poor crease recovery due to ________.

With all other parameters constant, the fabric with a low cover factor effectively transmits water vapor by a diffusion mechanism in comparison with that of fabric with a high cover factor due to ________.

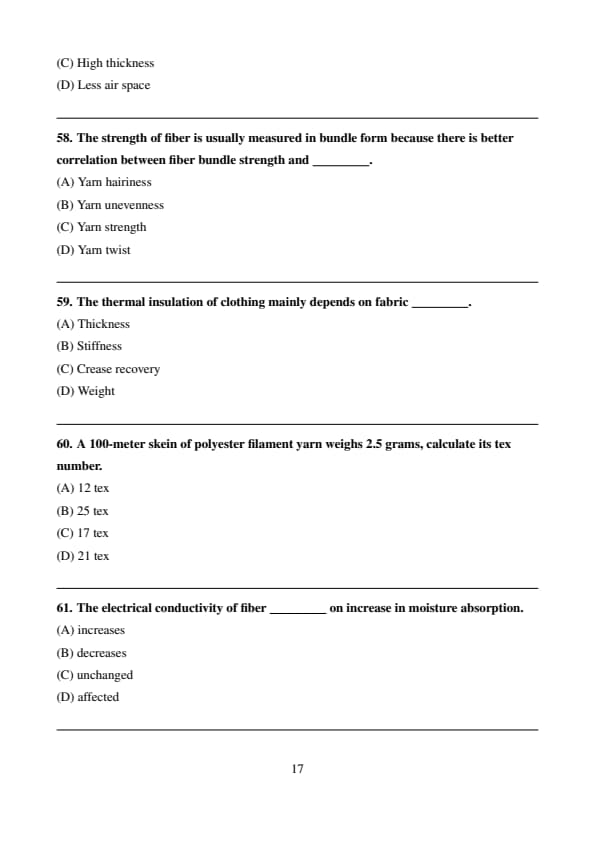

The strength of fiber is usually measured in bundle form because there is better correlation between fiber bundle strength and ________.

The thermal insulation of clothing mainly depends on fabric ________.

A 100-meter skein of polyester filament yarn weighs 2.5 grams, calculate its tex number.

The electrical conductivity of fiber ________ on increase in moisture absorption.

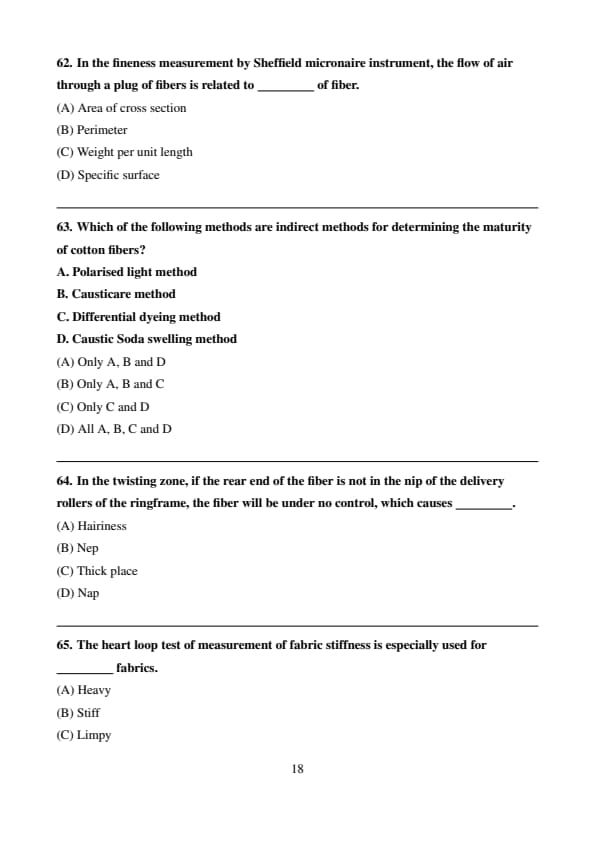

In the fineness measurement by Sheffield micronaire instrument, the flow of air through a plug of fibers is related to ________ of fiber.

Which of the following methods are indirect methods for determining the maturity of cotton fibers?

A. Polarised light method

B. Causticare method

C. Differential dyeing method

D. Caustic Soda swelling method

In the twisting zone, if the rear end of the fiber is not in the nip of the delivery rollers of the ringframe, the fiber will be under no control, which causes ________.

The heart loop test of measurement of fabric stiffness is especially used for ________ fabrics.

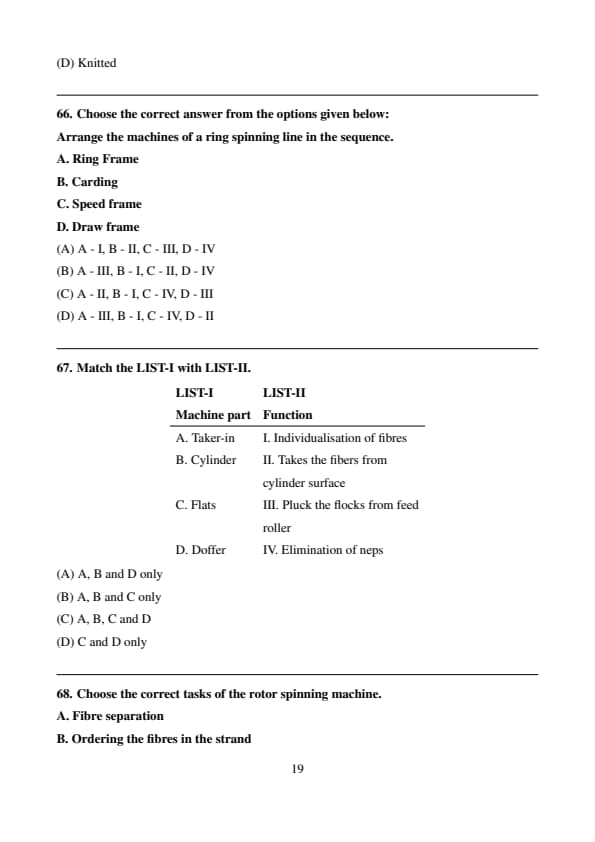

Choose the correct answer from the options given below:

Arrange the machines of a ring spinning line in the sequence.

A. Ring Frame

B. Carding

C. Speed frame

D. Draw frame

Match the LIST-I with LIST-II.

Choose the correct tasks of the rotor spinning machine.

A. Fibre separation

B. Ordering the fibres in the strand

C. Imparting strength by twisting

D. Removal of neps

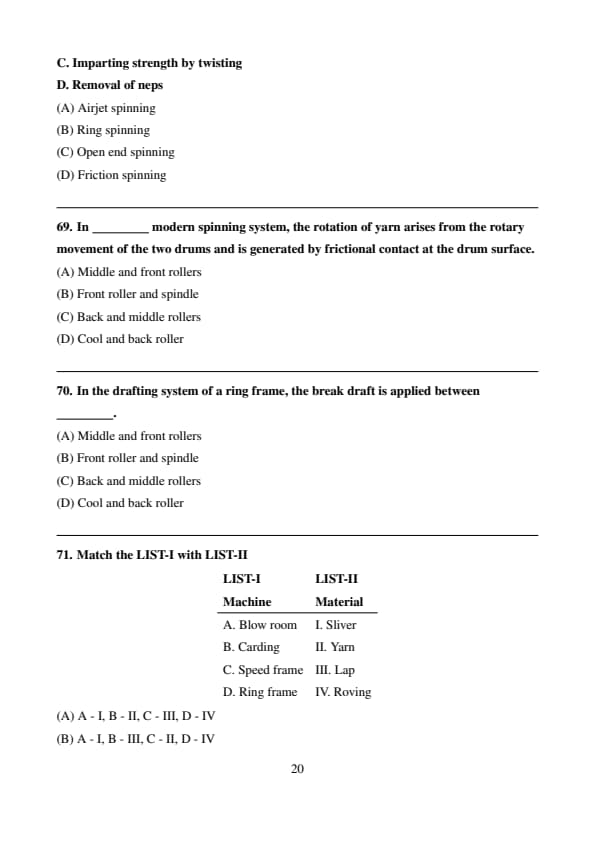

In ________ modern spinning system, the rotation of yarn arises from the rotary movement of the two drums and is generated by frictional contact at the drum surface.

In the drafting system of a ring frame, the break draft is applied between ________.

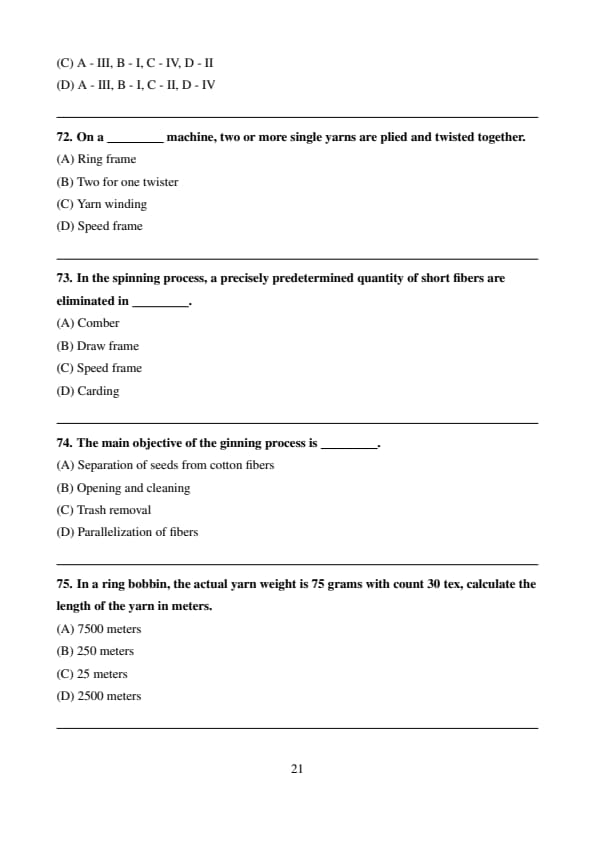

On a ________ machine, two or more single yarns are plied and twisted together.

In the spinning process, a precisely predetermined quantity of short fibers are eliminated in ________.

The main objective of the ginning process is ________.

In a ring bobbin, the actual yarn weight is 75 grams with count 30 tex, calculate the length of the yarn in meters.

Comments